Honda prepares for production start of solid-state batteries

Advantages of solid-state batteries

Solid-state batteries offer several advantages over current lithium-ion batteries in cars. Solid-state batteries have a higher energy density. This means they can store more energy in a smaller and lighter battery. This allows cars to achieve a greater range without making the battery larger or heavier. Thanks to the use of a solid electrolyte instead of a liquid one, solid-state batteries can charge faster. This is especially useful for electric cars, as charging times are often a stumbling block for consumers.

Also safer and lighter

Solid-state batteries are also safer. The solid electrolyte is less flammable than the liquid electrolyte in lithium-ion batteries, reducing the risk of overheating, fire or explosions. Also, these batteries wear out less quickly, meaning they can handle more charge cycles before capacity drops significantly. This makes solid-state batteries more durable and economical in the long run. Solid-state batteries function better in both extremely cold and hot temperatures. This is a big advantage for electric cars in different climate zones.

Through the use of other materials and a more efficient manufacturing process, solid-state batteries could potentially become less dependent on scarce resources such as cobalt and lithium. This could reduce environmental impact. Currently, however, they are still expensive to produce. Still, several car manufacturers are working on the technology, think Toyota, BMW and Volkswagen. And so is Honda.

Test production line of Honda

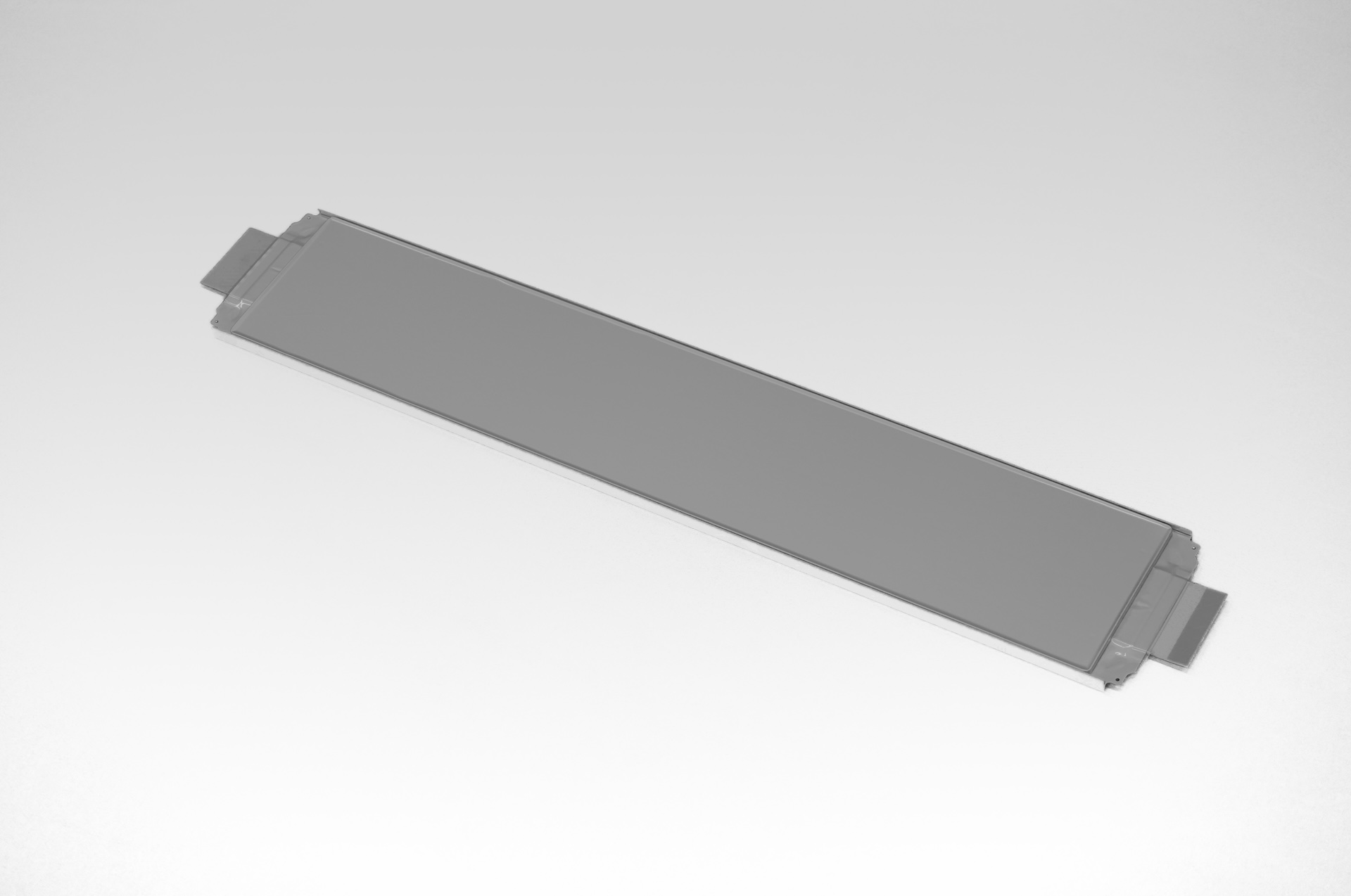

The production line should help Honda prepare for large-scale manufacturing. The demonstration line has a total floor area of about 27,400 m2 and is equipped with facilities and equipment that allow verification of each manufacturing process, including weighing and mixing electrode materials, electrode assembly coating and rolling, and cell placement in the module.

Construction of the facility building was completed in the spring of this year and almost all of the major equipment needed for verification is now also installed. Honda plans to begin battery production on this demonstration line in January 2025 and will verify mass production technologies and costs for each process while also developing battery cell specifications.

Reduce indirect costs

In addition, by consolidating and accelerating a range of assembly processes, including the joining of positive and negative electrodes, Honda will aim to significantly reduce the production time per cell. Moreover, Honda is also working to reduce the indirect costs of battery production, including energy consumption, by implementing various measures, including the introduction of production control technology that minimizes the low dew point environment required to ensure work safety and battery performance.

By increasing the cost competitiveness of fully solid-state batteries – through the application of a highly efficient manufacturing process and by expanding the application of the batteries to a wide range of Honda mobility products, not only cars but also motorcycles and aircraft – Honda aims to further reduce costs.

In the field of solid-state batteries, Honda is rapidly conducting research and development in two core areas – material specifications and production methods – with the goal of starting mass production of the battery in the second half of this decade.

Objective of Honda

Honda aims to achieve carbon neutrality for all Honda products and operations by 2050. Furthermore, all Honda vehicles should be battery-electric or fuel cell-electric by 2040.

Keiji Otsu, President and Representative Director of Honda R&D Co., Ltd, said, “The solid-state battery is an innovative technology that will be a gamechanger in this EV era. As a replacement for fuel engines, batteries will be the key factor of electrification. We believe advances in batteries will be a driving force in Honda’s transformation. Now the start of operation of our demonstration production line for our solid-state batteries is in sight.”